Universal Robots (UR), headquartered in Denmark, has begun to seriously develop the Japanese market, including significantly expanding its Japanese branch. UR is a pioneer in collaborative robots that can work in the same space as people without safety fences, and is the manufacturer with the world’s top market share. What is the company’s strategy for developing the Japanese market and what is the future of collaborative robots? We spoke with President Jurgen von Hollen, who visited Japan from Denmark.

Top share in collaborative robots

— Collaborative robots are attracting worldwide attention.

Several market research companies have released forecasts for the global collaborative robot market, and all of them predict that it will grow at a rate of 43-50% per year for the next few years. As of 2018, it is a small market that did not even reach 500 million dollars (55 billion yen, calculated at 110 yen to the dollar), but it is expected to grow to 9 billion dollars (990 billion yen, calculated at 110 yen to the dollar) by 2025. Even we, the largest manufacturer of collaborative robots, have no idea how big it will grow in the future.

–What is UR’s current market share?

Our share of the overall collaborative robot market is about 50-60%. As the overall market expands rapidly, we think it is important to maintain this share.

–I hear that collaborative robots are more prevalent in Europe than in Japan.

Looking at our sales ratios in the three regions of “Asia-Pacific,” “Europe,” and “Americas,” Asia-Pacific is 25%, Europe is 45%, and Americas is 30%. Europe is certainly a high sales ratio, as UR, which was born in Denmark, first targeted the market, but it is still only just beginning to be popular. The message has yet to reach potential users, and it can be said that the whole world, including Europe, is a market of the future.

–Are sales in Japan growing?

Although sales figures for Japan alone have not been released, the Northeast Asian region, including Japan, saw the highest growth rate in the Asia-Pacific region. Japan in particular is not only a large market, but also the country with the most advanced automation in the world, so it is important for us as a leading manufacturer of collaborative robots to have a strong presence in this country.

Strengthening the functions of the Japanese branch

–At the end of last year, we moved our Japan branch office from Chiyoda-ku to Minato-ku in Tokyo, and started operations at the new office this year.

This is a sign of our intention to put even more effort into developing the Japanese market. The new office is equipped with an application room where you can not only see the actual machine but also test it including peripheral devices, and a training center where you can learn how to use it. It is also our role as a market leader to spread information such as “What is a collaborative robot and how should it be used?” We do not only make and sell robots, but also propose them in the form of applications that “can be used like this” and provide solutions that help solve customers’ problems. For that reason, facilities like this are essential. Since the office is larger than before, we can increase the number of staff, such as engineers.

–We place importance on applications and solutions.

That’s right. We see collaborative robots as a platform to solve our customers’ problems. We combine the robot body with end effectors such as hands, various sensors, and other peripheral devices to build the optimal robot system. We certify the equipment required for this as “UR+ (plus)”. The equipment, including everything from hardware to software, has been confirmed to have the optimal specifications for our robots, and users can even program the equipment using UR’s teaching pendant (handheld control panel). Currently, there are about 140 UR+ certified products, but we plan to double that number by the end of this year. I think we will be able to introduce products from Japan’s leading peripheral device manufacturers as UR+ in the near future.

–140 products is a lot, but now it’s doubled. It seems like it would be difficult to choose because there are too many.

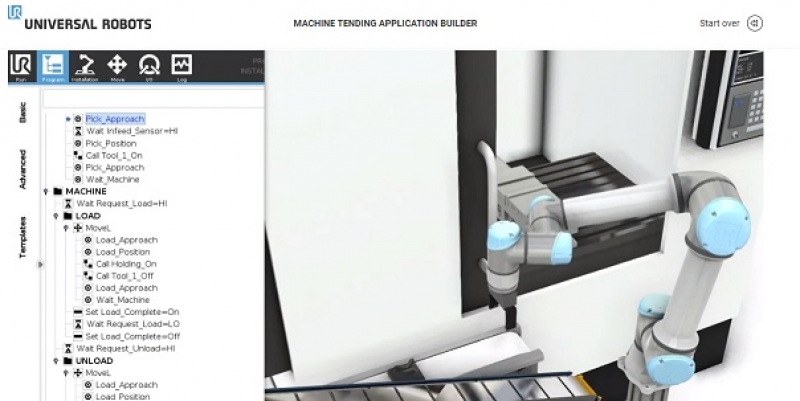

It’s not a big deal because we provide a service called “Application Builder” on our website. Just select the tasks and conditions you want the robot to perform, and the necessary peripheral devices will be listed. You can check the robot system built with those devices on video and see how it works, so there’s no need to worry about “it’s different from what you imagined when you actually put it together.” Programming is also easy because it comes with program templates according to the work content. When manufacturers narrow down the options for peripheral devices as packages or options, you have to compromise and use the manufacturer’s specified devices even if a different device would be more suitable. The work content and factory environment for robots are different for each site. In order to adapt to these diverse sites, it is necessary to be able to choose the best peripheral devices from the many options that fit our robots, rather than forcing them on you. The Application Builder is currently in English, but we plan to release the Japanese version this spring.

— In recent years, Japanese robot manufacturers have been entering the collaborative robot market one after another, and competition is increasing. How do you view the current situation of intensifying competition? Please tell us more about that in the second part.

Thank you.

–Continued in the second part

(Interviewer: Yuya Sone, Robot Digest Editorial Desk)

Jurgen von Hollen

has held senior management positions at international companies such as DaimlerChrysler Services, Deutsche Telekom and Pentair. He was Executive President of the Engineering Solutions division at Bilfinger SE, an international engineering services company. He joined Universal Robots in 2016. He holds an MBA from Henley Management College, UK.

コメント